Our Wood drying kiln

We can provide wood dryers for all kinds of factories, you can customize the wood kiln according to your needs, we will reply you within 20 minutes.

SWKD-4.0HFV Vacuum Wood Dryer

Capacity:4.4 cubic meters per full load

Out Dimension:5400x1716x1809mm. Timber Cart Size:4000x1100x1000mm.

SWKD-6.0HFV Vacuum Wood Kiln

Capacity:6.6 cubic meters per full load

Out Dimension:6500*1916*2006mm

Timber Cart Size:5000*1200*1100mm.

SWKD-8.0HFV Vacuum Lumber Kiln Dryer

Capacity:8.64 cubic meters per full load Out Dimension:7600x20000x2090mm Timber Cart Size:6000x1200x1200mm

SWKD-10.0HFV Wood Drying Machine

Capacity:10.08 cubic meters per full load Out Dimension:8600x2000x2090mm

Timber Cart Size:7000x1200x1200mm

SWKD-12.0HFV Vacuum Wood Dryer

Capacity:12.48 cubic meters per full load Out Dimension:9600x2000x2090mm

Timber Cart Size:8000x1300x1200mm

SWKD-14.0HFV Vacuum Timber Dryer

Capacity:14.56 cubic meters per full load Out Dimension:9600x2200x2090mm

Timber Cart Size:8000x1400x1200mm

SWKD-20.0HFV Vacuum Drying Equipment

Capacity:21.6 cubic meters per full load Out Dimension:9600x2700x2300mm

Timber Cart Size:8000x1800x1500mm.

Customized wood Kiln for Wood Block

For the thick wood block it is take super long time to finish the drying process by conventional kiln.In order to save this problem, we developed the high frequency vacuum kiln for wood block.

High Frequeny vacuum dryer kiln for veneer

The fresh peeling veneers, it’s only take 20-30 hours to finish the whole process of veneer drying by the high frequency veneer dryer.

Main Advantages Of High Frequency Vacuum Drying Technology

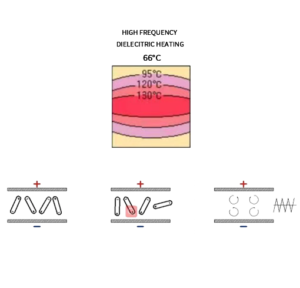

Working Principle & Process

High frequency wave can penetrate wood deeply and dry wood from core to wood surface wholly and uniformly from the ever beginning. Even thick wood can also be well heated. Meanwhile under vacuum condition, wood moisture can be boiled at 50-60 degree and vaporize rapidly, which can save both time and energy. And low temperature wood drying can guarantee wood quality to avoid crack problem. Vacuum system will suck wood moisture out due to pressure difference which double increases wood drying speed. The result of the combination is that even more than 50cm thick wood can dried by our high frequency vacuum wood dryer machine with uniform moisture content within two weeks. Normally Drying time for one cycle is 7-12 days

wood drying kiln's Key Advantages

1.Stable drying without defects

The wood is drying under vacuum condition,it is Low boiling point of water,it can be vaporized at 50℃.

Low temperature drying solves the problems of wood cracking, deformation and discoloration, especially for precious timber sensitive to temperature.

- Fast drying

High Frequency medium heating make the wood heated very fast, Temperature Gradient of Internal High and External Low and vacuum pressure make water dischaged out very quickly.The 8cm thick Africa rosewood from 40-50% moisture content only take 7 days to reach 8-10% moisture content.

- High quality drying result

High frequency vacuum wood dryer machine equipped with hydralic pressure system on top, the hydralic pressure system supply more than 4 tons presser on the wood stacking to prevent wood deformaing and bending.We use stainless steel 304 to make the pressure plate.

- Easy operation

PLC control system and Pneumatic system make it is easy to opetat.Automatic drying make it no need staff on duty during the drying process.

- High quality high frequency vacuum wood dryer machine

Our high frequency vacuum wood dryer machine is made of stainless steel to avoid corrison and rust.

6.Insecticidal eggs:

HF vacuum dryer can be installed quickly and moved easily when renovations or expansions are required

7.Easy to handle

HF vacuum dryer can be installed quickly and moved easily when renovations or expansions are required

Main Parts of high frequency vacuum wood dryer

1. High frequency generator is the core technology of our kiln, the main function is transfer electricity into high frequency power. The PLC control system also in the high frequency generator

2. Square shapre vacuum oven the our patent design,it is easy to stack wood and load more woods

3. The auto cooling systerm is consist of cooling tower,built-in condeser and External condenser.

The function is for condensating hot moisture and separating water from air.

4.We use Taiwan hydraulic pressure sytem and stainless hydro-cylinders.

Supply more than 6 tons pressure on the wood to keep it straight.Wood drying kiln is a good way to dry wood.

5. There is an motor on timber feeding cart. It will save labor to load and unload the wood stacking.

6.Srainless steel vacuum pump and electromagnetic valve Also stainless steel case,more corrosion resistant

Problems We Solved

Bending, cracking after drying process

Compared with conventional steam kiln, high frequency is kind of directly heating, under the electricity filed, wood will be heating inside and outside at the same time, the vacuum dehydration technology make the wood drying process under an vacuum and wet condition at low temperature. That will ensure wood is no cracks and keep the wood nature color. Meanwhile our machine is equipped with hydraulic system on the top, it can keep 6 tons pressure during whole drying process. That will ensure wood no bending

Long preparation and hard to control the drying quality

For the traditional drying process and kilns the wood drying process the preparation period is long, the operation is complicated and wood drying quality is closely related to the workers, while for Shuowei products, we adopt simple structure which is easy to install, panel display ensures stable and reliable drying results with little request of operation.

Money locked down for a long time drying circle

Cash flow is very important to company, especially in wood industry, the earlier you make wood to wood products, the faster you get money. As proved by the actual performance, HF vacuum dryer offer a significant reduction in drying times. Sometimes it takes only one tenth time of the traditional ways, so Out-turn percentage of timber has increased, your cash flow is much healthier.

After-sales Service

- Provide users with important technical information for operation and maintenance. Combining with the network and remotely.

- Provide technical and business training for equipment installation, commissioning, operation, and maintenance. When necessary, experienced engineering and technical personnel could be sent to provide on-site technical services in time .

- After receiving the user’s complain of the quality problem , It is guaranteed to reply within 24 hours and provide a solution within 48 hours, and the service will not stop if the user is not satisfied with the solution

- Easy to install and start, taking only a few hours to get the program up and running

- When used properly, machine parts are rarely damaged

- Lifetime after-sales service

Application Case

Application cases of high frequency vacuum dryer kiln around the world by Hebei Shuowei Metal Manufacturing Co.

High Frequency Vacuum Dry Kiln in Zambia

High Frequency Vacuum Kiln in Canada

Full Auto Type High Frequncy Vacuum Dry Chamber Installed in Unite States

HF vacuum wood dryer in Indonesia

Our Happy Clinets From 80+ Countries

Have more questions please contact us

Business Team

Technical Support

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right HF wood dryer you want.