SWKD-6.0HFV Vacuum Wood Dryer Kiln

SWKD-6.0HFV High Frequency Vacuum Wood Dryer is one of the best seller in the medium capacity of products. Especailly in Vietnam, Indonesia and Thailand Area.

SWKD-6.0HFV Vacuum Wood Dryer Kiln

High frequency vacuum wood dryer machine is advanced wood drying equipment, which only needs electricity without boiler, environment friendly and easy to handle with.

Comparing with conventional kiln dryer,high frequency vacuum wood dryer machine capacity is small and flexible, less factory space needed; efficiency is much higher (more than 10 times faster than kiln dryer). After seasoning, timber is kept straight and in high quality without cracking.

Out-turn percentage of timber increased. HF vacuum wood dryer machine is the best choice for small and medium furniture manufacturers.

Specification of SWKD-6.0HFV Vacuum Wood Dryer Kiln

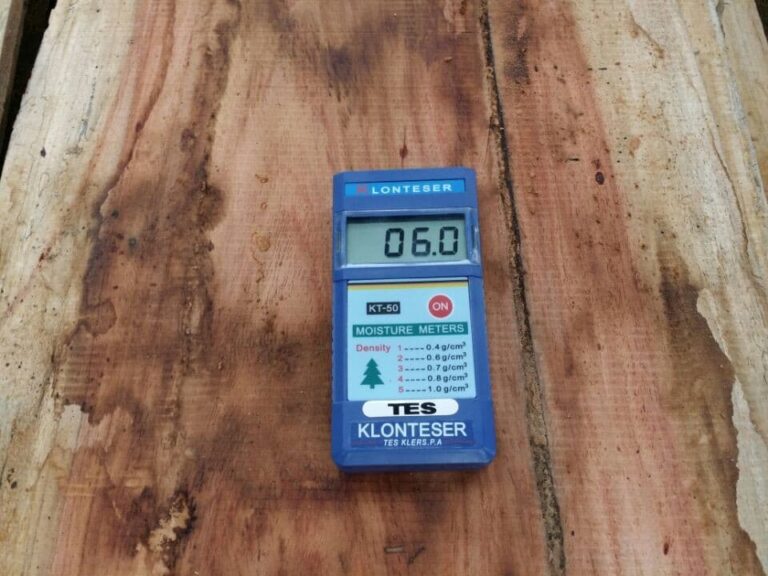

1,The 2″ thickness mahogany wood from 30-40% moisture content only take 6 days to reach 6-8%MC.Uniform Moisture content, no bending, no cracking.

2,Penetration heating on the plate is the biggest advantage of High frequency dry,to dry wood inside and outside at the same time.

This high-frequency characteristics will be doomed its mahogany and hardwood lumber drying class has unique advantages.

| Model | SWKD-6.0HFVHigh Frequency Vacuum Wood Dryer |

| Capacity | 6.6 cubic meters per full load |

| Out Dimension | 6500*1916*2006mm |

| Timber Cart Size | 5000*1200*1100mm |

| Max Length of Wood | 5000mm |

| High Frequency | 6.78MHz |

| Vacuum pressure | -0.093Mpa |

| Weight(kg) | 5000 |

Main Features of SWKD-6.0HFV high frequency vacuum wood dryer

1.Stable drying without defects

The wood is drying under vacuum condition,it is Low boiling point of water,it can be vaporized at 50℃.

Low temperature drying solves the problems of wood cracking, deformation and discoloration, especially for precious timber sensitive to temperature.

- Fast drying

High Frequency medium heating make the wood heated very fast, Temperature Gradient of Internal High and External Low and vacuum pressure make water dischaged out very quickly.The 8cm thick Africa rosewood from 40-50% moisture content only take 7 days to reach 8-10% moisture content.

- High quality drying result

High frequency vacuum wood dryer machine equipped with hydralic pressure system on top, the hydralic pressure system supply more than 4 tons presser on the wood stacking to prevent wood deformaing and bending.We use stainless steel 304 to make the pressure plate.

- Easy operation

PLC control system and Pneumatic system make it is easy to opetat.Automatic drying make it no need staff on duty during the drying process.

- High quality high frequency vacuum wood dryer machine

Our high frequency vacuum wood dryer machine is made of stainless steel to avoid corrison and rust.

Our Customers

Many customers from the world are benefitting from the high frequency drying technology, if you want make your drying process easier and faster, welcome contact us

Vacuum kiln in the Unite States

Vacuum kiln in the Vietnam

Vacuum kiln in the Unite States

Why choose us Shuowei?

We do our best to provide you with better service and support before wholesaling our products

Rich experience: Focus on the wood drying industry for more than 30 years, master the drying methods of various wood species, and have a most comprehensive drying data collected

Strong R&D Capacity: Shuowei owns a professional engineering team (led by two drying experts with more than 30 years and 12 young engineers with 6-10 years) and provides customers with professional technical support and drying project solutions

Customized services: According to the customers’ requirements,we can customize the exclusive equipment which is suitable for the work conditions and needs

After sales service: Super long warranty, free replacement of accessories within the warranty period, free after-sales service for life, 24-hour after-sales service all day, and solve after-sales problems anytime and anywhere

Strict Quality control – For electronic components we use the best (Schneider brand) , and stainless steel is used for anti-corrosion vacuum oven. The equipment has been tested in aspects of power, pressure, air tightness etc., throughout the production and before leaving the factory to ensure the operation quality of the equipment. It has passed the all-round quality inspection of SGS, BV and other international testing institutions

High praise from customers: The customers are all over the world including United States, Canada, South Korea, Japan, Indonesia, Thailand, Vietnam, Malaysia, Australia, New Zealand, European countries and Africa. The industry involves furniture factory, floor factory, cabinet factory, wooden door factory, wooden handicraft factory, etc., Shuowei has been highly praised by customers

Have More QuestionsPlease Contact Us

Business Team

Our business team can help you with the price and shipping costs calculations. Come On! Be a member of high frequency vacuum wood dryer kiln users, make your wood drying process easier and faster.

Technical Support

Our technical teams are rich experiences in wood drying, if your any question about wood drying, especially for difficult drying hardwood block,slab,and special wood species drying questions. welcome contact us.

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the HF wood dryer you want.